The world's largest tensioning distance:

The DoRa ratchet load binder

So short...

... and yet so long!

A long tensioning distance as well as its handiness are particularly important characteristics for the user-friendly and fast work with ratchet load binders.

The result of our development department's work is astounding. A ratchet load binder was developed that achieves a tensioning distance that is 89% longer (almost twice as long) than the one of conventional ratchet load binders – despite a 18% shorter overall length and identical performance characteristics.

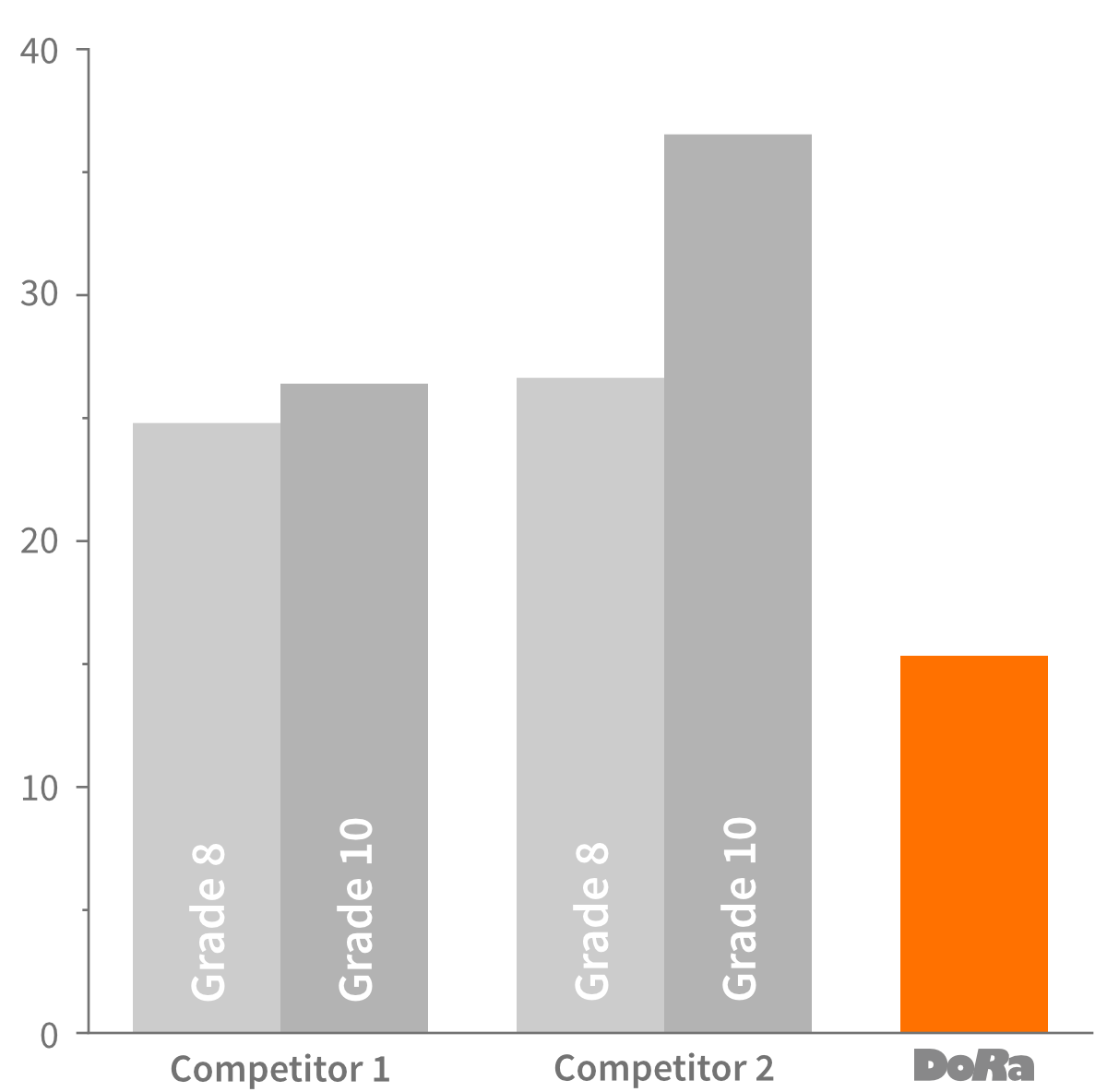

Also special about the DoRa: Taken the ratio between overall length and tensioning distance as a basis it achieves more than 100% tensioning distance. For comparison: A standard binder makes only half of that.

More than 100% tensioning distance

| DoRa | Standard* | |

|---|---|---|

| Overall length | 289 mm | 352 mm |

| Tensioning distance | 304 mm | 161 mm |

| Ratio | 105 % | 46 % |

* Average value of conventional ratchet load binders

And best of all, an extra adapted DoRa hook now securely connects the DoRa binder to the DoNova® lashing chain.

This allows you to enjoy all the advantages of the super-light textile chain and the DoRa binder in its minimal design with maximum tensioning distance at the same time - efficient and flexible working is then guaranteed!

Weigth characteristic value

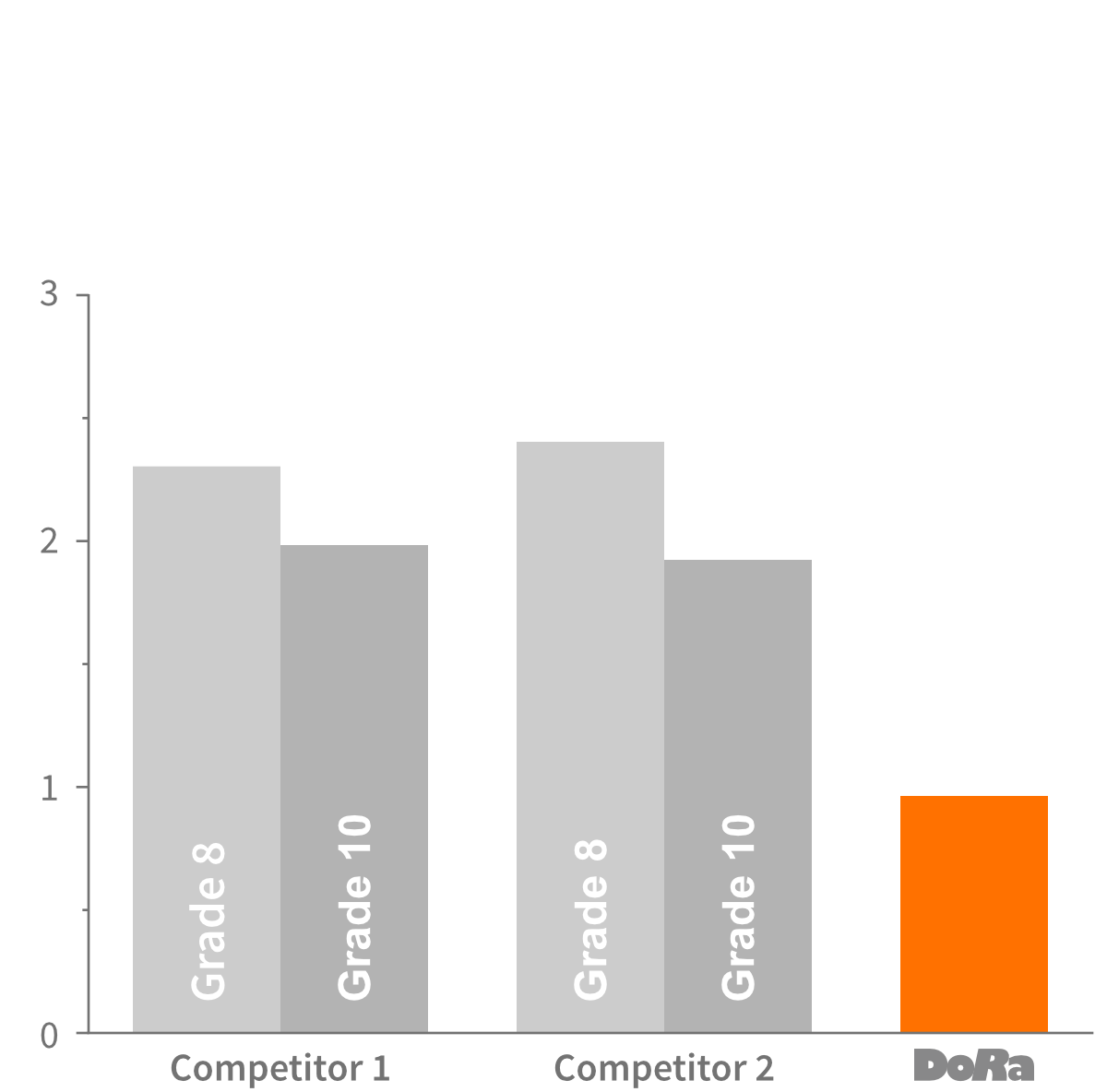

With the help of the weight characteristic value, the ratio between weight and tensioning distance of different ratchet load binders can be compared. The lower the weight and the greater the tensioning distance, the smaller it becomes. So a small weight characteristic value - just like a small length characteristic value - stands for particularly user-friendly handling.

Weight characteristic value = Weight / Tensioning distance

Length characteristic value

The length characteristic value describes the ratio between the overall length and the tensioning distance of a ratchet load binder. The shorter the overall length and the greater the tensioning distance, the smaller it becomes. A small length characteristic value thus stands for particularly user-friendly handling.

Length characteristic value = Overall length / Tensioning distance

Less exertion of force due to extremely large tensioning distance

Use possible also at limited space due to compactness

Easy re-tensioning due to tensioning distance "reserves"

Time-saving due to faster handling

| 1 | Easier and faster lashing! |

When attaching lashing chains, they must first be hand-tightened, hooked into the shortening elements provided and then tensioned. The extremely large tensioning distance of the DoRa ratchet load binder makes for the hooking into chain links that are farther away from each other – without sagging of the lashing chain after the tensioning process. Thus, especially when using thick or long chains less force is required to tighten and hook in the chain.

| 2 | Big in the smallest places |

… since the DoRa ratchet load binder is – despite its large tensioning distance – extremely compact. Thereby, it can be comfortably used where lashing chains have to be tensioned in conditions of limited space.

| 3 | Easy and fast re-tensioning |

During transit, lashing chains can come loose due to shift of the cargo and thus, have to be re-tensioned. The large tensioning distance "reserve" of the DoRa ratchet load binder minimizes the need for it to be detached and re-tensioned for that purpose. The available tensioning take-up is sufficient to enable the easy re-tensioning at the initial position of the ratchet load binder.

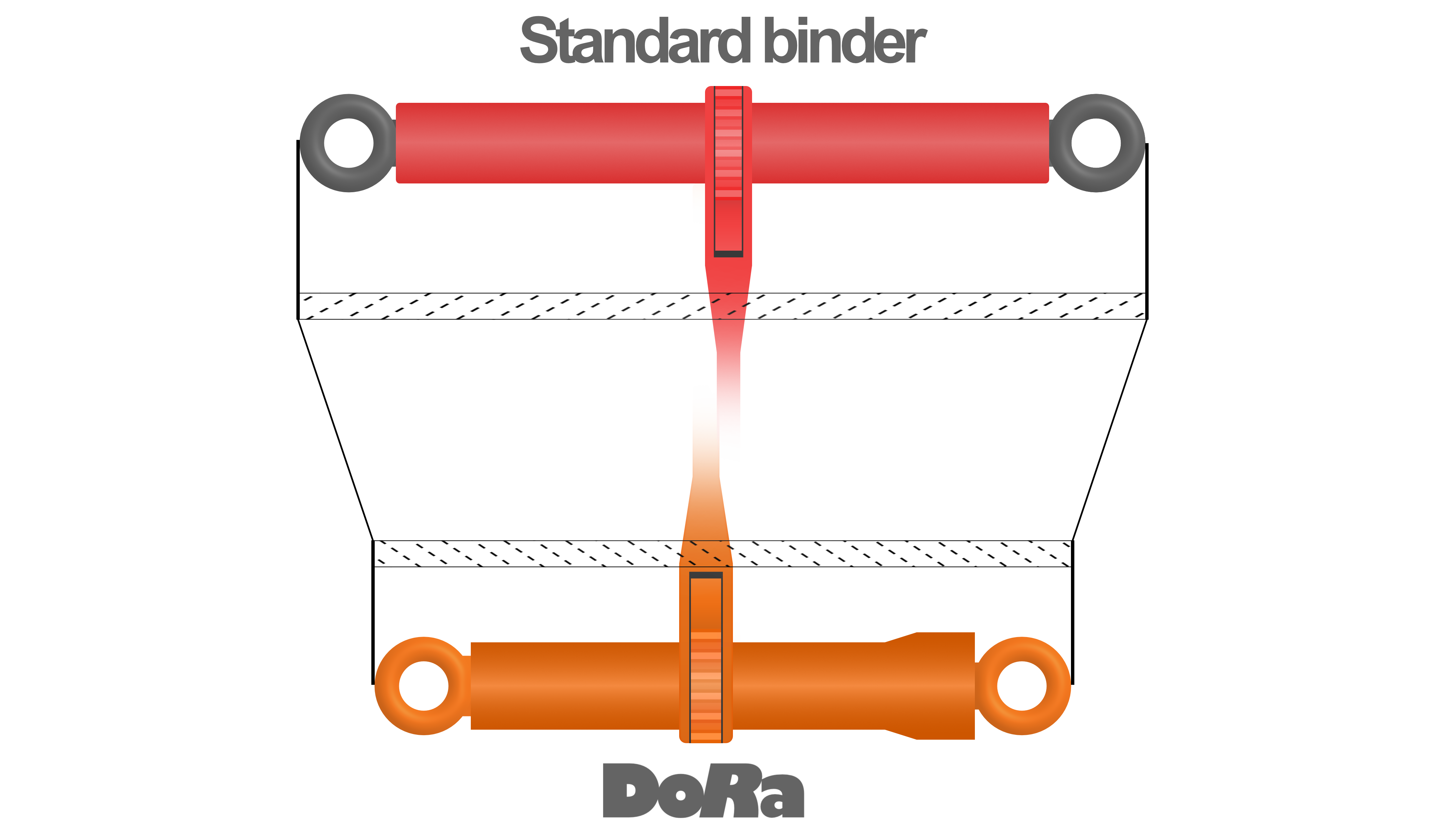

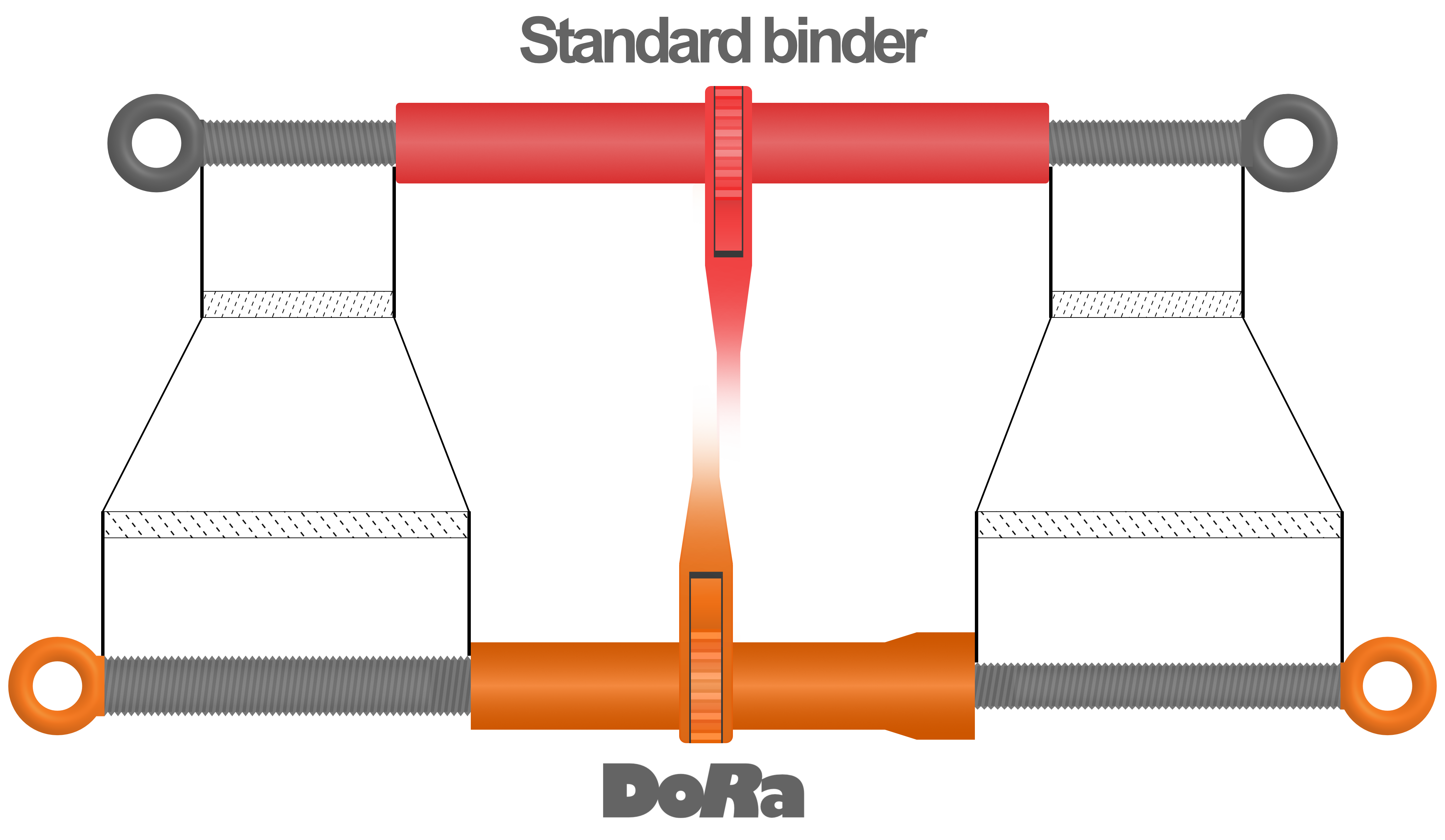

The trick: A new constructional principle

The secret of this unique ratio between tensioning distance and length is in the DoRa’s constructional principle. Instead of two identically designed threaded spindles that are rotated "against each other" with the closed tensioner, the DoRa ratchet load binder has two different tensioning spindles.

One spindle has a larger diameter and is hollow inside, while the other has a smaller diameter and fits inside the hollow space in the larger spindle. In the closed (retracted) state, one spindle is screwed into the other.

Specifications of steel lashing chains with DoRa100 ratchet load binder (whole system)

| Part no. | Type of system* | Nominal thickness | WLL (daN) | STF (daN) | Standard length (m) |

|---|---|---|---|---|---|

| 1940 4001 | one-piece | NG 8-8 | 4.000 | 1.000 | 3,50 |

| 1940 4002 | two-piece | NG 8-8 | 4.000 | 1.000 | 3,50 |

| 1940 5001 | one-piece | NG 8-10 | 5.000 | 1.250 | 3,50 |

| 1940 5002 | two-piece | NG 8-10 | 5.000 | 1.250 | 3,50 |

| 1940 6301 | one-piece | NG 10-8 | 6.300 | 1.575 | 3,50 |

| 1940 6302 | two-piece | NG 10-8 | 6.300 | 1.575 | 3,50 |

| 1940 8001 | one-piece | NG 10-10 | 8.000 | 2.800 | 3,50 |

| 1940 8002 | two-piece | NG 10-10 | 8.000 | 2.800 | 3,50 |

*One-part: with shortening claws; Two-part: with separate lashing chain

DoRa100 specifications for use with steel chains (only load binder)

| Part no. | For system* | Nominal thickness | WLL (daN) | STF (daN) |

|---|---|---|---|---|

| 0385 0081 | one-piece | NG 8-8 | 4.000 | 1.000 |

| 0385 0085 | two-piece | NG 8-8 | 4.000 | 1.000 |

| 0385 0082 | one-piece | NG 8-10 | 5.000 | 1.250 |

| 0385 0086 | two-piece | NG 8-10 | 5.000 | 1.250 |

| 0385 0083 | one-piece | NG 10-8 | 6.300 | 1.575 |

| 0385 0087 | two-piece | NG 10-8 | 6.300 | 1.575 |

| 0385 0084 | one-piece | NG 10-10 | 8.000 | 2.800 |

| 0385 0088 | two-piece | NG 10-10 | 8.000 | 2.800 |

DoRa100 ratchet load binder for use with textile chain DoNova®

| Part No. | For system** | Nominal thickness | WLL (daN) |

|---|---|---|---|

| 0385 0101 | For textile chain DoNova® PowerLash | 25/8 | 10.000 |

**With DoNova® shortening hooks on both sides